Contents

So, take a look at the finer details of inventory and inventory management and finance to ensure your business achieves steady growth. It is an attempt to solve these twin problems that an financial order quantity model was developed. Information on fifteen objects comprised of 10 non-seasonal and 5 seasonal items was collected from a supermarket in Ikot Ekpene city, Nigeria.

With the help of AS 2 – “Valuation of Inventories” and Ind AS 2 – “Valuation of Inventories”, inventory components shall be valued and classified as assets. The values of the inventory components have to be regularly checked and updated to provide for depreciation, deterioration and obsolescence to arrive at the accurate values. Inventory accounting helps in the calculation of the reorder levels. Through this, the business never runs out of stock since orders are placed on time.

For example, let’s say your fixed costs are 100, demand per year is 1000 units and the carrying cost per unit is 2 then the EOQ is 316 units. Organizations mainly use this technique for controlling spare parts of inventory. Like, a higher level of inventory is required for vital parts that are very costly and essential for production.

We at IndianMoney.com update all the new terms used in personal finance in the Financial Dictionary. You can refer and update yourself, to serve clients effectively. This is a double bonanza of increasing your efficiency and fetching clients more money.

The carrying cost includes warehouse fees and opportunity costs. If the inventory is destroyed or stolen from the warehouse then it can be a part of the carrying cost. If you are paying interest to purchase inventory, then the amount you are paying to the bank should be made part of the carrying costs. The insurance costs with regard to the inventory are also taken into account in carrying cost calculation.

Carrying costs are variable costs as they will depend on your inventory. Economic Order Quantity is the amount that minimizes all these prices. In this paper, a multi-item multi-period stock management drawback with all items and/or incremental amount low cost policies beneath restricted storage capacity is offered. The impartial random demand rates of the items in the intervals are identified and the objects are provided in distinct batch-sizes.

It is extremely important to know what the financial terms mean when signing on terms and conditions. When availing financial products, you can be easily cheated if you don’t know what you have signed up for. To avoid this, you must be aware on what the terms really mean. With the assumption that https://1investing.in/ demand is constant, the quantity of stock can be seen to be depleting at a constant rate over time. When inventory reaches zero, an order is placed and replenishes inventory. This means you need to have at least 60 collars in the inventory to ensure you are rightly stocked at any given time.

Types of inventory by function

Inventory, being a current asset, is an essential component of the working capital of the business. Based on the customers’ demand for the goods, the inventory is divided into fast, slow, and non-moving goods. By properly analysing the inventory needs, cash will not be trapped in unnecessary inventory.

The accounting and valuation of inventory have a significant bearing on the financial statements of the business. To ascertain the value and cost of inventory, the business must consistently ensure that inventory accounting is carried out. To determine the proper amount of inventory, you must estimate needs based on historical demand. If you’re using spreadsheets and don’t have any tracking in place, this can be time-consuming.

The stock summary report gives details regarding the stock-in-hand on a particular date. Details about the stock’s quantity, rate, and closing values are integral in the stock summary report. One of the unique features of this report is that it gives you the information on a real-time basis. If you are planning to avail a Home Loan, then it is crucial for you to understand under what conditions your bank is sanctioning the loan.

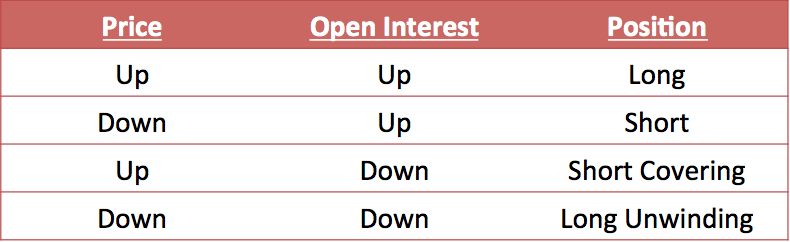

Based on the connection between buyers and suppliers, it’s necessary to have a mannequin that integrates stock management model between consumers and suppliers. If the order quantity is increased to 2,200 items, fewer orders [26,000 / 2,000] might be positioned. However, average stock readily available will increased to 1,000 [2,000 / 2] units. The optimum financial order amount is reached on the lowest point on the entire value curve. That’s the point at which ordering prices equal carrying value – or the financial order amount.

If overstocking happens, the material costs of the organisation would become high. Whether it is for purchasing inventory management software, have a team or head in place at your warehouse, or doing audits, you can finance all your needs by taking a working capital loan. Typically, working capital finance for SMEs is given collateral-free for tenors ranging from 12 months to 60 months.

Why use EOQ?

In other words, it is the optimal inventory size that should be ordered from the supplier to reduce the business’s total annual inventory cost. Economic order quantity is also referred to as optimal order size and optimal order quantity. Order quantity is a major consideration—ordering too many items raises your holding costs, while ordering too few items can result in an out-of-stock situation.

Safety stock is simply excess inventory that exceeds expected demand. Safety stock is also frequently used during peak shopping seasons such as the holidays or during a big promotion or flash sale. Furthermore, if the company had not invested in the product under consideration, it could have been used for something else. It can take the form of godown space or storage area rentals, as well as electricity bills, repairs, and maintenance. Then there’s the cost of human resources to keep the stock in good condition.

That will assist it in reducing inventory storage costs and help it to maintain a healthy cash flow at all times. In this formula, the alphabet D indicates the demand of the number of additional units you require of a specific stock. The alphabet S indicates the cost of setting up the demand and the alphabet H indicates the cost of storage of an additional unit of the said item. You save a lot of money on storage which can be utilised in other departments like research, promotional activities, marketing or even training.

What Is The EOQ Formula (Economic Order Quantity)?

The demand remains constant according to the assumptions made by EOQ. The demand is how much inventory is used per year or how many units are sold per year. An indispensable technique used by all commercial enterprises known to stock inventory.

The fact that the EOQ is dynamic and can be revisited as your business grows makes it a compelling tool. If any of your inventory costs change, you can always tweak the formula and generate a new EOQ to reflect the new conditions. By tracking inventory in real-time, you can easily monitor and control stock levels, as well as know where products are stored in your warehouse.

If the company can achieve the above, it helps them to minimise the inventory costs like the holding and order costs, the delivery and supply costs, etc. Keeping the inventory cost in check is highly important for the companies as it provides a sense of security to the company and the cash savings in this form can be used for a number of purposes. Economic order quantity allows a business organisation to conduct efficient management of its inventory. Without EOQ, business organisations would develop a tendency to hold either excessive or deficient amounts of inventory. This would result in missed opportunities and high inventory costs.

- The EOQ is the optimum amount of goods to order every time to reduce complete inventory costs.

- It can take the form of godown space or storage area rentals, as well as electricity bills, repairs, and maintenance.

- With no excess inventory in hand, the company saves the cost of storage and insurance.

- Instead of manually checking inventory levels to reorder products, you can set automatic reorder points that place an order automatically when your inventory levels reach a certain threshold.

- This production-scheduling mannequin was developed in 1913 by Ford W. Harris and has been refined over time.

Ensure you keep track of such items as well when planning your inventory. Safety stock is the inventory you would ideally hold in case in case of unexpected delays in receiving fresh stocks. Here is a formula to help you calculate the safety stock number. While it is very necessary to maintain the optimum level of inventory, it is not so easy as well. definition of eoq Nonetheless, some models or methods have been developed in the recent past for determining the optimum level of inventories to be maintained in the enterprise. Different scenarios have been created to simulate the fuzzy logic EOQ after which the results of the conventional method, EOQ technique, and fuzzy EOQ methods have been obtained and compared.

EOQ Formula Calculators

As a result of inconsistent reordering, this could result in stockouts or excess inventory. The EOQ model is a straightforward model for products that have consistent demand all year. Newly launched products may have a higher initial demand that fades over time.

With the EOQ model, the organization is able to place the right quantity of inventory. JUST IN TIME Method– In Just in Time method of inventory control, the company keeps only as much inventory as it needs during the production process. With no excess inventory in hand, the company saves the cost of storage and insurance. The company orders further inventory when the old stock of inventory is close to replenishment. This is a little risky method of inventory management because a little delay in ordering new inventory can lead to stock out situation.